A resina de polivinil butiral (PVB) é amplamente utilizada em revestimentos, tintas, adesivos, suspensões cerâmicas e filmes devido às suas excelentes propriedades de formação de filme, adesão, resistência ao impacto e boa compatibilidade com diversos materiais. Diferentes cenários de aplicação impõem diferentes requisitos à viscosidade, à proporção de grupos funcionais e à solubilidade do PVB. Portanto, compreender as características estruturais e as aplicações de diferentes especificações de PVB é fundamental para obter formulações estáveis e controlar os custos.

1. Compreendendo o PVB: A estrutura química determina as propriedades físicas.

O PVB é uma resina sintética produzida pela reação de condensação do álcool polivinílico e do butiral sob catálise ácida. Controlando-se precisamente três indicadores químicos principais, definem-se as aplicações de diferentes graus de pureza:

2. Classificação das especificações do PVB e divisão da faixa de viscosidade

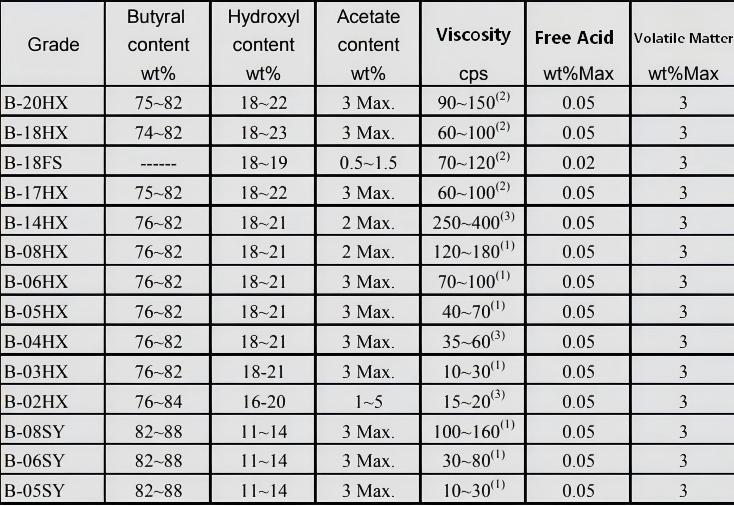

Do ponto de vista da aplicação industrial, os principais critérios de distinção do PVB concentram-se no grau de viscosidade e na composição dos grupos funcionais. A série CCP PVB pode ser amplamente classificada em três categorias com base na viscosidade da solução: baixa viscosidade, viscosidade média e alta viscosidade.

Graus de baixa viscosidade, como Resina PVB B-02HXAs resinas PVB B-03HX, PVB B-04HX, PVB B-05HX e PVB B-05SY geralmente apresentam boa fluidez em sistemas com baixo teor de sólidos, tornando-as adequadas para sistemas com altos requisitos de trabalhabilidade, como revestimentos por pulverização, tintas de baixa viscosidade ou sistemas de dispersão com alto teor de carga. Esses produtos ajudam a melhorar a molhagem do pigmento e a uniformidade da aplicação, garantindo a continuidade do filme.

Graus de viscosidade média (como CCP PVB B-06HX, Os polímeros CCP PVB B-08HX, CCP PVB B-06SY e CCP PVB B-08SY apresentam um bom equilíbrio entre fluidez e resistência estrutural, tornando-os mais adequados para revestimentos de uso geral, tintas compostas e sistemas adesivos. Eles proporcionam adesão estável e resistência mecânica em condições normais de sólidos e são frequentemente utilizados em formulações industriais.

Graus de alta viscosidade, tais como Changchun PVB B-14HXOs PVB B-17HX, PVB B-18HX e PVB B-20HX da Changchun são adequados para aplicações que exigem alta resistência da película, resistência ao impacto ou coesão, como camadas adesivas de alto desempenho, revestimentos funcionais e adesivos estruturais. Esses produtos são normalmente usados em sistemas com alto teor de sólidos, que requerem condições de dissolução e dispersão relativamente mais rigorosas.

Além da viscosidade, o desempenho do PVB também depende muito da proporção de grupos butiraldeído, hidroxila e acetato em sua molécula. Na série CCP PVB, a maioria dos produtos do tipo HX apresenta um teor relativamente equilibrado de butiraldeído e hidroxila, resultando em boa solubilidade em diversos solventes polares, mantendo ao mesmo tempo boa adesão e resistência à água. Em contraste, a série SY (como a série CCP PVB) apresenta um teor de butiraldeído e hidroxila relativamente baixo, resultando em boa solubilidade em diversos solventes polares, mantendo ao mesmo tempo boa adesão e resistência à água. Resina PVB B-05SYOs PVBs Changchun B-06SY e Changchun B-08SY são produtos com alto teor de butiraldeído e alto grau de acetalização. Esses PVBs possuem uma menor proporção de grupos hidroxila polares em suas cadeias moleculares, apresentando, portanto, melhor compatibilidade com sistemas de solventes apolares ou fracamente polares, sendo particularmente adequados para formulações à base de tolueno e solventes ésteres. Sua estrutura formadora de filme é mais compacta, o que contribui para melhorar a resistência à água e a estabilidade química.

3. Cenários típicos de aplicação

Em revestimentos e tintas, o PVB da série HX, de baixa a média viscosidade, é frequentemente utilizado como dispersante de pigmentos ou resina formadora de filme. Sua boa compatibilidade permite seu uso sinérgico com diversos sistemas de resina, reduzindo a dependência de aditivos na formulação.

No campo das tintas de impressão, o PVB de viscosidade média proporciona um melhor equilíbrio entre adesão, flexibilidade e velocidade de secagem, tornando-o particularmente adequado para o tratamento de superfícies de substratos metálicos, plásticos ou compósitos.

Para adesivos, os produtos de PVB de alta viscosidade ou da série SY são mais vantajosos. Sua maior coesão e resistência da película ajudam a melhorar a durabilidade e a resistência ao impacto da camada adesiva final. Em algumas formulações, diferentes tipos de PVB também podem ser misturados para ajustar com precisão a viscosidade do sistema e as propriedades de aplicação.

Site: www.elephchem.com

WhatsApp: (+)86 13851435272

E-mail: admin@elephchem.com