A borracha de cloropreno modificada com tiol desempenha um papel crucial em sistemas adesivos de borracha de cloropreno devido ao seu mecanismo único de controle de polimerização. Os produtos modificados com tiol, especialmente as séries SN24, SN244X e SN23, são amplamente utilizados em adesivos para calçados, adesivos em spray, adesivos universais de alta qualidade, adesivos decorativos para arquitetura e interiores automotivos.

1. Mecanismo de Modificação de Tióis

Durante a polimerização de borracha de cloropreno (CR)Os modificadores afetam significativamente a taxa de polimerização, o peso molecular, a distribuição e a controlabilidade do processo de polimerização. Os modificadores tiólicos, devido à sua reatividade moderada, são amplamente utilizados na produção de borracha cloropreno adesiva.

1.1 Processo de Polimerização Mais Estável

A modificação com tiol controla eficazmente o crescimento da cadeia, mantendo o peso molecular e a distribuição adequados, resultando em boa solubilidade e propriedades de processamento estáveis. Isso afeta diretamente a viscosidade do adesivo, as características de formação de filme e a estabilidade de armazenamento a longo prazo.

1.2 Determinação da aderência inicial e da resistência final dos adesivos

Tomando como exemplo a série SN24, a estrutura molecular obtida por meio da regulação de tióis apresenta uma resistência superior na formação de filmes. Quando enxertada com MMA (metacrilato de metila), melhora significativamente a adesão a diversos substratos, resultando em maior aderência inicial e maior resistência de ligação final.

1.3 Impacto no Horário de Abertura e na Janela de Trabalho

A série SN23 foi projetada especificamente para "tempo de abertura ajustável". Através do controle meticuloso da estrutura molecular, ela proporciona tempos de aplicação mais flexíveis para as indústrias de calçados e decoração, melhorando efetivamente a conveniência operacional e a eficiência da produção.

A regulação de tióis não se resume a um simples controle da polimerização; trata-se de um meio técnico fundamental que influencia o desempenho da aplicação de todo o sistema adesivo, fornecendo uma base técnica sólida para cenários de colagem complexos.

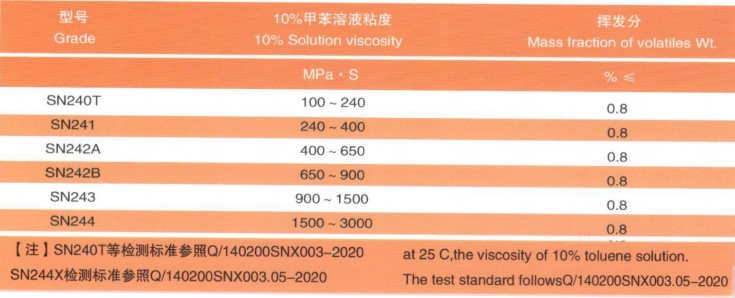

2. Desempenho e valor de aplicação da série SN24/SN244X

Entre as borrachas de cloropreno com tiol regulado, as séries SN24 e SN244X são as que mais atraem a atenção do mercado. A SN24 foca na resistência da ligação e em aplicações de enxertia, enquanto a SN244X otimiza ainda mais a solubilidade, a cor e a resistência às intempéries, resultando em um desempenho geral mais completo.

2.1 Série SN24: Produtos básicos de alta resistência, enxertáveis e de ampla aplicação.

♠ As principais características da série SN24 incluem:

Sistema modificado com tiol para controle estável do peso molecular

A adaptabilidade do enxerto de MMA melhora ainda mais a adesão a substratos como metais, couro e borracha.

Alta aderência inicial e excelente resistência de colagem final.

Adequado para sistemas de colagem rápida

♠ Aplicações típicas:

Adesivos para calçados na indústria calçadista

Adesivos em spray nas indústrias de móveis e embalagens

Adesivos avançados de uso geral e adesivos de engenharia

Borracha de cloropreno SN-242A É um produto amplamente utilizado, extensivamente adotado em aplicações adesivas para calçados devido à sua resistência, rápida velocidade de colagem e facilidade de uso.

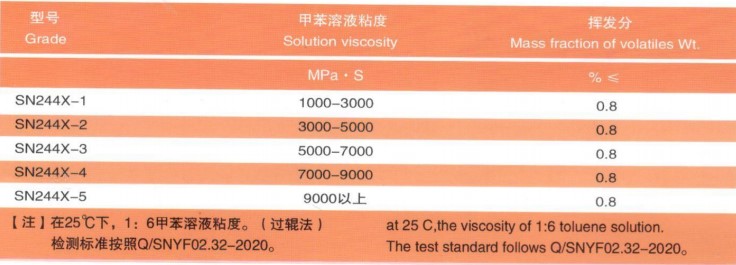

Série 2.2 SN244X: Produtos aprimorados com alta solubilidade, cor clara e alta resistência às intempéries.

Borracha de cloropreno SN-244X A série otimiza diversas propriedades-chave com base no SN24, tornando-o uma borracha de cloropreno modificada com tiol de qualidade superior e mais estável.

♠ As principais vantagens incluem:

Dissolução mais rápida, melhorando a eficiência da produção.

Cola de cor mais clara, adequada para produtos de cores claras ou com aparência delicada.

Alta resistência inicial de adesão, longo tempo de fixação e melhor resistência às intempéries.

Menos propenso ao envelhecimento após a colagem, adequado para ambientes externos ou com forte luminosidade.

♠ Aplicações típicas:

Adesivos de calçados de alta qualidade

Adesivos para construção e decoração

Colagem de interiores automotivos

Indústrias de móveis e decoração

Para empresas que necessitam de "dissolução rápida + forte adesão + alta resistência às intempéries", a série SN244X é uma escolha típica.

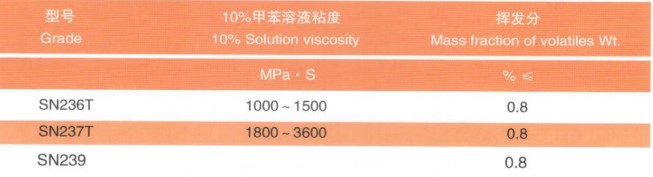

3. Série SN23: Produtos complementares especificamente projetados para ajustar o tempo de abertura.

Diferentemente da aplicação direta do SN24 e do SN244X, a série SN23 atua como um "modificador" em sistemas adesivos de cloropreno. Sua principal função é ajustar o tempo de abertura.

3.1 Por que o tempo de funcionamento é tão crítico?

Em aplicações adesivas, um tempo de abertura muito curto dificulta a aplicação; um tempo de abertura muito longo reduz a eficiência. Diferentes estações do ano, temperaturas de aplicação e condições do substrato podem causar variações no resultado final da colagem.

A série SN23 permite o ajuste preciso da velocidade de secagem e da faixa de operação do adesivo, garantindo um desempenho estável em diversas condições ambientais.

3.2 Resultados aprimorados quando usado em conjunto com SN24/SN244X

A série SN23 normalmente não é usada sozinha, mas sim em combinação com as séries SN24 e SN244X, servindo aos seguintes propósitos:

Prolongar ou otimizar o tempo de abertura do adesivo.

Melhoria na pulverização e na sensação de aplicação.

Otimizar o equilíbrio entre as velocidades de ligação inicial e final.

Aprimorando a adaptabilidade a processos complexos

Produtos típicos como SN236T e SN237T possuem viscosidade de solução adequada e boa estabilidade, o que os torna altamente valiosos nas indústrias de calçados e adesivos industriais.

À medida que setores como o de fabricação de calçados, decoração de móveis e interiores automotivos exigem cada vez mais desempenho dos adesivos, a borracha de neoprene de grau adesivo está entrando em uma fase de desenvolvimento focada em maior desempenho, maior controle e maior estabilidade.

♣ As séries SN24, SN244X e SN23 modificadas com tiol são componentes-chave dessa tendência:

SN24 – Alta resistência, enxertável e com propriedades adesivas abrangentes

SN244X – Uma solução aprimorada que oferece dissolução rápida, cor clara e alta resistência às intempéries.

SN23 – Um modificador de tempo aberto que torna a produção mais controlável.

Por meio da combinação adequada, esses adesivos podem criar sistemas adesivos de neoprene mais estáveis, fáceis de processar e mais adaptáveis, proporcionando maior eficiência e melhor qualidade de colagem para as indústrias usuárias finais.

Site: www.elephchem.com

WhatsApp: (+)86 13851435272

E-mail: admin@elephchem.com